Intec Foams are a long established supplier of PE Foam, a closed cell Polyethylene foam produced in cross-linked or non cross-linked versions.

With over 30 years’ experience in creating foam, we are able to design and produce any PE Foam to your requirements. We work to tight tolerances and have an excellent turnaround time. With a proven track record within the foam industry. Please see our recent case studies for examples of new foams developed

Cross linked PE foam has superior physical properties. It is a strong and resilient, RoHS Compliant, eco friendly and non-toxic closed cell foam. This makes it ideal for applications in the Food Industry, medical & healthcare, bespoke packaging and more.

PE Foam comes in a range of different types and grades. Each one may be suited to a particular purpose or application. If you would like a foam made for your particular requirements, please contact us

- Plastazote Foams ( LD15, LD18, LD24,LD29, LD33 & LD45)

- Evazote Foams (EV30 & EV50)

- Supazote EM26

- Sekisui Alveo Foams

- Palziv Foams

- Stratocell Foams (Antistatic available)

- Cross linked and non cross linked

- Colour Foams are available in some grades such as yellow, green, red & blue. Black and white are standards.

PE Foam is one of the most versatile foams we supply. Its inherent properties make it ideal for a huge range of applications.

Properties

- Closed cell – does not allow the ingress of water

- Low Density – lightweight

- Chemically Inert – Good for food related applications with some FDA approved

- Excellent Impact & Shock Absorption – a very good packaging foam

- Excellent Chemical Resistance

- Excellent UV and Ozone Resistance – does not readily degrade

- Excellent thermal and chemical sterilization for medical devices

- Excellent Thermal Insulation

- Temperature Resistance Typically: -40˚C to +90˚C

Incredibly versatile properties make PE Foam ideal for use in a range of environments and for many applications.

- Floatation & Buoyancy Devices – Lifejackets, Canoe Buoyancy

- Medical – Orthopaedics, Suture pads, Medical Device Packaging

- Seals & Gaskets (with or without self-adhesives)

- Anti – Vibration Pads which can be kiss cut on rolls.

- Shock Absorption Pads, Boat Fenders, Crash Mats

- Building & Construction – Sound Insulation. Thermal Insulation (Frost Blankets), Eaves Fillers, Expansion Joints

- Packaging (Presentation Packaging, Tote Trays, Cushion Packaging, Edge Packaging, Corner Protection, Point of Display),

- Pond and Swimming Pool Covers

If you have a new idea or use for PE foam and want to discuss if it is possible, or looking for advice on the next stage, please contact us and we’ll be happy to help.

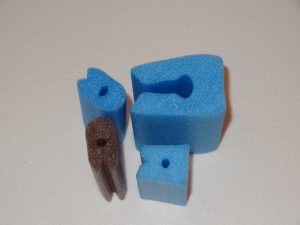

PE Foam Extrusions and Profiles

- Lightweight

- Excellent repeated shock absorption

- Closed cell

- Wide range of shapes and sizes

- Aesthetically pleasing for packaging

- Chemically inert

- Highly resistant to chemicals

- Compatible with all sealing materials

- Environment riendly: free of CFC, HCFC and chemical blowing agents

- 100% recyclable

- Light weight, flexible material, easy to install

- Waterproof

Available Profiles (click to expand)

Typical Applications:

- Backer rod for cold sealing applications (up to +90ºC)

- Filling gaps before applying sealants and mastics in expansion joints

- Floatation devices

- Draught Sealer

- Filling joints in concrete and masonry

- Plugs for filling circular holes

- Exercise Rollers

Originally designed to protect car windscreens, our screen protection coils are ideal for protecting virtually any form of screen or sheeting or during handling and movement.

Screens and sheets which suffer knocks and bumps to their edges whilst in transit can chip and/or crack and this can be detrimental to the quality of the entire screen. Sheets with damage to their edges might even be completely unusable should they be required to create a tight seal, as is the case with window panes and shower enclosure panels. Employing the use of our foam screen protection coils then is advisable for preventing monetary loss caused by windscreens and the like becoming damaged unnecessarily during delivery.

The foam profile can be easily fitted all around your sheet or screen, and is then commonly packaged in shrink film.

One of the big advantages of using this type of foam edge protection is that the screen remains fully visible (you can see if the window is broken) , which is not the case with traditional corrugated packaging.

Typical Applications:

- Protection of glass panes

- Protection of thin sheets

- Protection of screens

- Solar Panels

- Display Panels

Foam U and UGT-channels are one of the most popular types of edge protection. Economical, easy to handle and to manipulate.

These foam profiles have been developed to efficiently protect the most sensitive parts of the product – the edges. Thanks to the tension of its lips, the U-shape grips the edges automatically.

Available in different sizes, our innovative edge protection foam can also be used to effectively protect corners from potential knocks and abrasions too The use of foam edge protectors will benefit longer term as companies suffer far fewer losses resulting from customer receipt of damaged items. Those moving edged furnishings to a new home meanwhile will also find the product invaluable.

Typical Applications:

- Doors

- Baths & Sinks

- Window frames

- Radiators

- Marble Fireplaces

- Delicate items on Building Sites

Goods which are not adequately protected in transit can incur damage. Customers who receive damaged items are sure to be left unhappy and will no doubt expect a refund. Such worries do not exist when using our durable, cost-effective L-profile foam edge protectors however.

L Profile is a non scratching foam providing excellent protection for many applications. This versatile foam can be easily cut to length and held in place with cling-film.

Typical Applications

Protection For:

- Furniture & Furnishings

- Worktops

- Display Products

- Low Cost packaging

Foam Corner protectors are ideal for ensuring that delicate corners do not get damaged in transit.

Products in transit are particularly susceptible to damage and so it is important to employ extra protection in these areas.

Our foam corner protectors are an ideal solution.

Typical Applications:

- For the protection of pictures

- Protection of photo frames

- Fridge freezers

- Paintings

- Mirrors

- Books

- Glass tabletops

- Any item where corners are compromised

C-shaped lengths of foam, manufactured in PE foam. Can easily be converted to corners and frames to protect sensitive items in transit, avoiding unnecessary waste.

Sensitive electronic devices that contain for instance microchips can get damaged in transit. This damage will prevent the product from operating correctly (if at all) and your business will be responsible for covering the cost of a replacement. To avoid profit loss, it is imperative to provide additional protection for such products and for this our foam shock absorption protection – which comes in different sizes for your convenience – are ideal.

This product absorbs the energy produced by shocks and vibrations, and provides optimal transport protection. The hollow shape is a key factor in shock absorption whilst the outside skin is designed to provide additional mechanical strength.

Typical Applications:

- The protection of delicate/sensitive items such as microscopes, computers, laptops, Blu-Ray players and other electronic devices

- Shock Absorption for delicate larger items

Uses (click to expand)

Protective PE foam tubes for encasing posts in playgrounds, gyms, Nursery’s etc. This version has a hard wearing protective film on the surface.

Typical Applications:

- Excellent UV resistance

- Hard Wearing

- Excellent protection

- Available in Red, Yellow, Blue and Green

- Protective cover on the tube

- Size: 2m x 87mm od x 50mm id (MOQ of )

For Health & Safety issues, scaffold poles need to be both protected and easily identifiable to reduce the risk of people walking into them and becoming injured. The foam is coloured yellow for High Visibility.

Black Tape can be wound round to give more of a distinct look.

Size: 2m x 70mm od x 50mm id (MOQ of 40).

Once door frames have been created in new builds or renovated houses, it is a good idea to protect them whilst other work continues or furniture is moved in. This 114mm diameter x 13mm wall thickness. It has a Fire Retardant rating to DIN 4102 B1

The tube can be easily opened out via the slit in the sidewall and slid onto the door frame (or jamb) to protect from knocks.