Melamine Foam

Melamine Foam is a low-density, open-cell polymer material, which offers specific benefits in certain applications, particularly where sound absorption, fire retardant, heat and chemical resistance are required.

Melamine Foam, thanks to its versatility, can be used in simple as well as technically demanding foam applications

Melamine is a flexible, lightweight foam material suitable for a range of uses.

Melamine Foam Properties :

- Low Density (11 Kg/m³) – low weight factors

- Wide temperature Range up to 240°C [465°F]

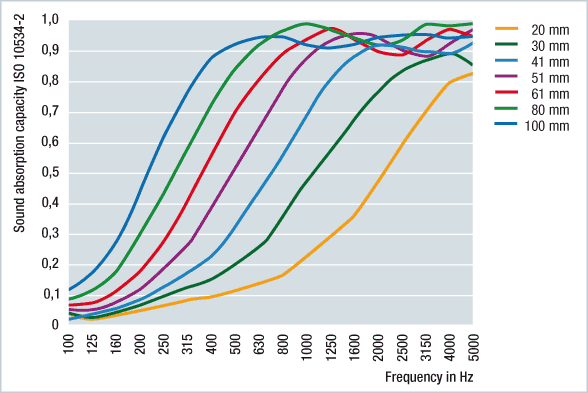

- Excellent Acoustic Properties

- Excellent Thermal Insulation

- Excellent Low Temperature Flexibility

- Constant physical properties over a wide temperature range

- Flame Resistance

- Abrasiveness

Typical Melamine Foam Applications

Melamine foam is used in a variety of applications. The most common ones are:

- Ceiling Tiles & Wall Panels in Public Transport

- Baffles in Sound Recording Studios.

- Suspended Ceiling baffles/Traps in buildings with high ceilings in the Construction Industry.

- Heating, Ventilation & Air Conditioning linings, Pipe Lagging.

- Aircraft Seating

- Cleaning & Spillage

- Thermo-formable Automotive Parts

- Low Temperature Insulation of Liquid Gas Tanks

- Heat & Noise Management in Cars

Melamine foam can be laminated to other high specification facings such as foil, Kevlar fibres, glass cloth amongst others.

New Ultra-light versions are available for Aerospace applications at 6 Kg/m³ for weight saving and thus fuel savings.

Melamine has the ability to be compression moulded to give unique shapes.