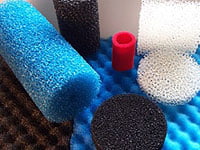

PU Foam (Polyurethane) including Polyester and Polyether Foams

We are a supplier, creator, and converter of all types of PU Foam for industrial and commercial applications. These include medical foams, construction, environmental, safety, sealing, and other applications. PU foam is used for many different purposes, and can range from a sponge type foam to denser and more resilient rubber types.

The unique properties of PU foam also means that it is classed a sponge like material. In fact, the early types of this type of foam were created to mimic a natural sponge, and as such as used for this type of application. Intec Foams has the ability to create shapes from these grades for bespoke applications that require a low density application.

Reticulated PU Foams

Reticulated foams are different to other foams in that the cell windows have been destroyed by a “Zapped” Reticulation process. Available in in polyether and polyester grades and different porosities.

Polyether Reticulated PU

- 10ppi to 60ppi for aquatic and pond filtration

- 100ppi is available.There is a special 50 – 65ppi that has been developed for HME Filters and a 75ppi for Ink reservoirs, ink rollers and ink pads.

Polyester

- 10ppi to 90ppi for air and gas filtration.

- Q110ppi (a special chemical etching reticulation process called “Quenching”) developed for cosmetic and medical applicators. This has a large MOQ

Applications and Usage

- Water Filters

- Pond Pump Filters

- Tertiary Sewage Tank Filters

- Heat & Moisture Exchange Filters

- Cosmetic Foams

- Air Filters

- Ink Reservoirs

- Pre-Cursor’s for Ceramic or Metal Filters

- Many More

Sealtec PU Foam

Sealtec PU foam is a type of foam consisting of polyether and polyester grade foam particular suited for low compression seals, used mainly in the automotive industry. It replaces EPDM foam where weight saving is a factor. Sealtec foam only needs around 60% compression to be effective.

Typical applications

- Automotive lamp cluster seals

- Automotive door seals

- Caravan window and skylight seals

Sealtec Aqua PU Foam (new product)

Sealtec – Aqua has been developed to provide reliable sealing against gases, liquids and particulates at reduced levels of compression, in comparison to traditional PU sealing foams which have inferior qualities. Needs only a 30% compression to achieve a seal.

Key Features v’s conventional PU foams for sealing

- Improved Durability

- Improved Hydrolytic Stability (better in water/moisture)

- Lower compression to create a seal

- Fine cell structure

- Soft

- Low density

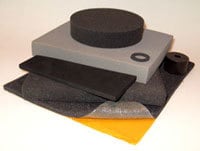

Firetec PU Foam

Available in polyether and polyester versions, with UL94 HF1 and V0 grades of fire retardancy which is an important factor in many electronic and acoustical applications. Also to BS 476 part 6 & 7 Class O for the Building & Construction Industry

Typical Uses:

- Lining of Electrical/ Electronic Cabinets

- Lining of Acoustic Hoods and Generator Housings

- HVAC panels for acoustic applications

- Transfer rollers in high tech business machines

- Prison Cell Mattresses

- Fire-blockers for seating applications in aircraft

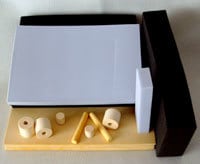

SAF (Shock Absorption Foams) Visco Elastic PU foams

A familiar feeling foam, as it is very similar to memory foam. This exhibits improved visco-elastic behaviour similar to Conforfoam™ but at a fraction of the price. Ideal for comfort management and protective padding applications especially shock absorption foam products.

- Soften and conform when exposed to heat.

- Virtually pressure free support

- High energy absorption (up to 97% of an impact)

- Resist Compression set

Typical Uses:

- Wheelchair Cushions

- Medical slings

- Wrist rests

- Shoe Insoles

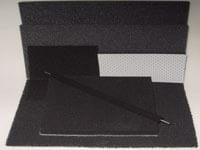

Felted Foams

These are special grades of PU foams that are thermally compressed until the foam takes a compression set. Effectively, this treatment increases the density, reduces the pore size and makes the foam firmer.

This is especially effective when taking a reticulated foam and felting it. By reducing the cell size, it creates a structure which creates a “Wicking” effect and draws in liquids into the foam structure. Ideal for the creation of an ink reservoir.

The foam can be compressed by several factors, only restricted by the height of the daylight press and the final thickness required.

Typical Uses:

- Ink rollers

- Ink pads

- Acoustic pads

- Filters

- High density padding

Most PU foams can be felted and some others too.

Special grades:

Polyurethane Foams can be developed to give specific properties or adding to existing grades

- Automotive Foam Types

- Anti-Microbial & Biocide additives to Resist Growth of mould/mildew

- Anti-Static

- Edge weldable

- Water Seal (Superseal)

- Low Permeability

- Thermoformable

- Hydrophilic – (Absorbs water)

- High Elongation – Neoprene Replacement

- UV Stabilised foams (Staywhite)

- Many Others

Intec Foams manage both large and small enquiries, we are here to help.

Should you have a specific requirement or enquiry for these products or any other potential application, please give us a call on 01283 225796 for a friendly impartial discussion, or simply complete our online web form or email us at: [email protected] and we will respond immediately.